TOUTE NOTRE GAMME D’ÉLECTROLYTES POUR ANODISATION

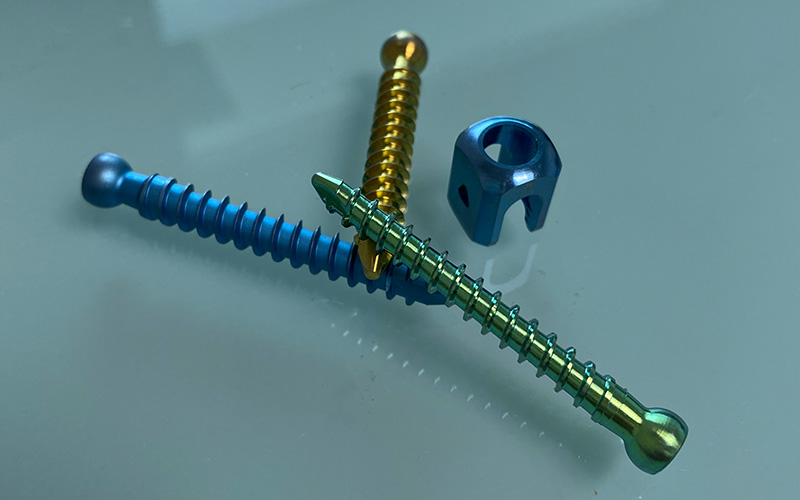

“On vous annonce la couleur”

Appliqués en immersion, nos électrolytes procurent à vos pièces en titane une bonne résistance à la corrosion et vous permettent d’obtenir en plus un large panel de couleurs.

ÉLECTROLYTES POUR ANODISATION

NOTRE GAMME POUR ANODISER LES TITANES

Découvrez toute notre gamme d’électrolytes et leurs différentes applications.

De plus, n’hésitez pas à nous contacter pour trouver le produit qui correspondra le mieux à votre besoin.

>>Electrolyte pour anodisation Aupus ANOD TI

>>Electrolyte pour anodisation Aupus ANOD TI+

LE PROCÉDÉ

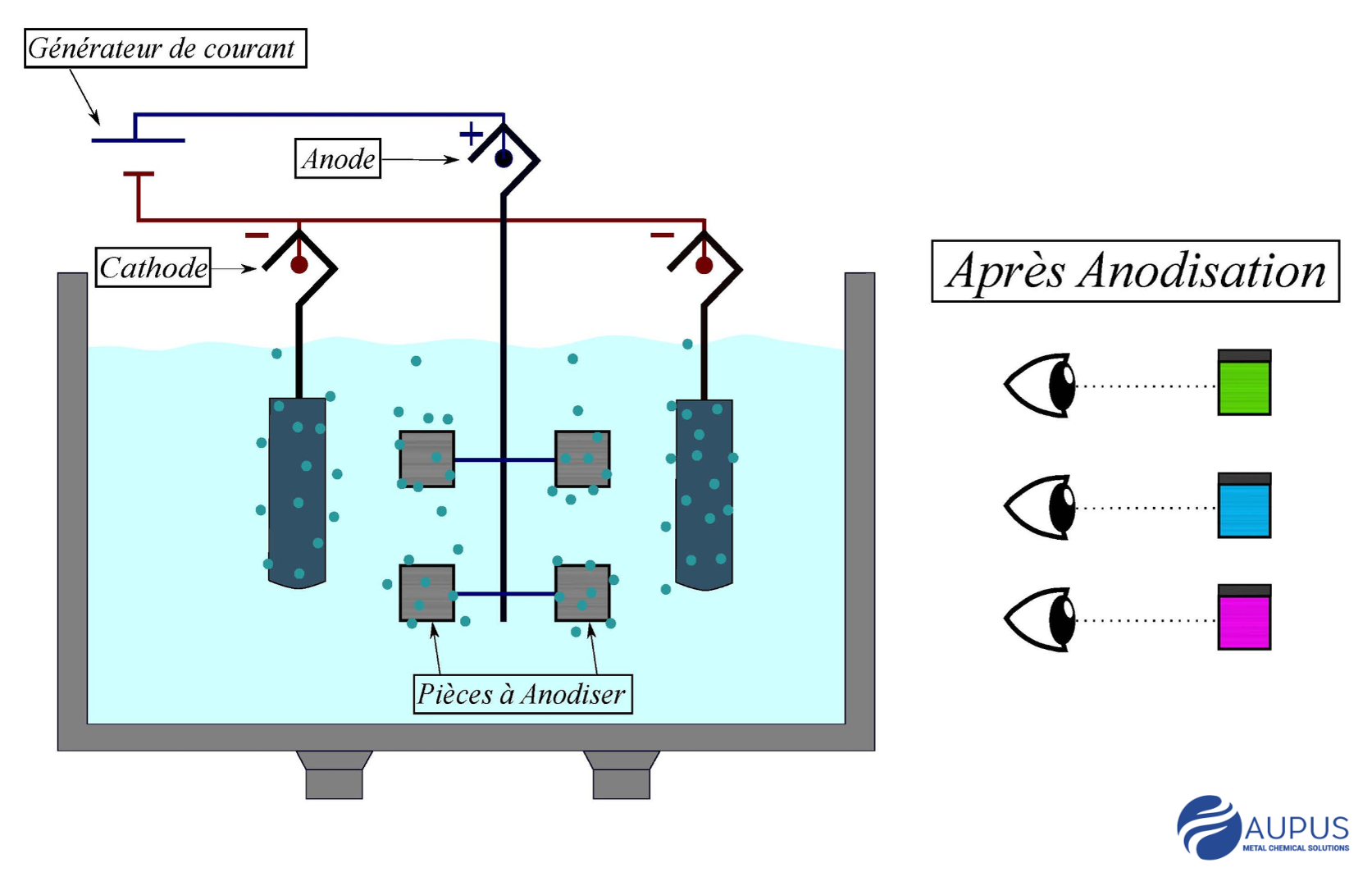

QU’EST-CE-QUE L’ANODISATION ?

L’anodisation ou oxydation anodique du titane consiste à créer par électrolyse une couche d’oxyde de titane uniforme qui va protéger la pièce. En fonction de la tension appliquée lors du traitement, l’épaisseur de la couche d’oxyde va varier. En fonction de cette même épaisseur, la couleur du titane va changer et générer un large spectre coloré. Nos produits peuvent être combinés à nos lignes de traitement. En premier lieu, nous préconisons un décapage des pièces au préalable avec notre produit Aupus DEC TI pour un résultat d’anodisation optimal.

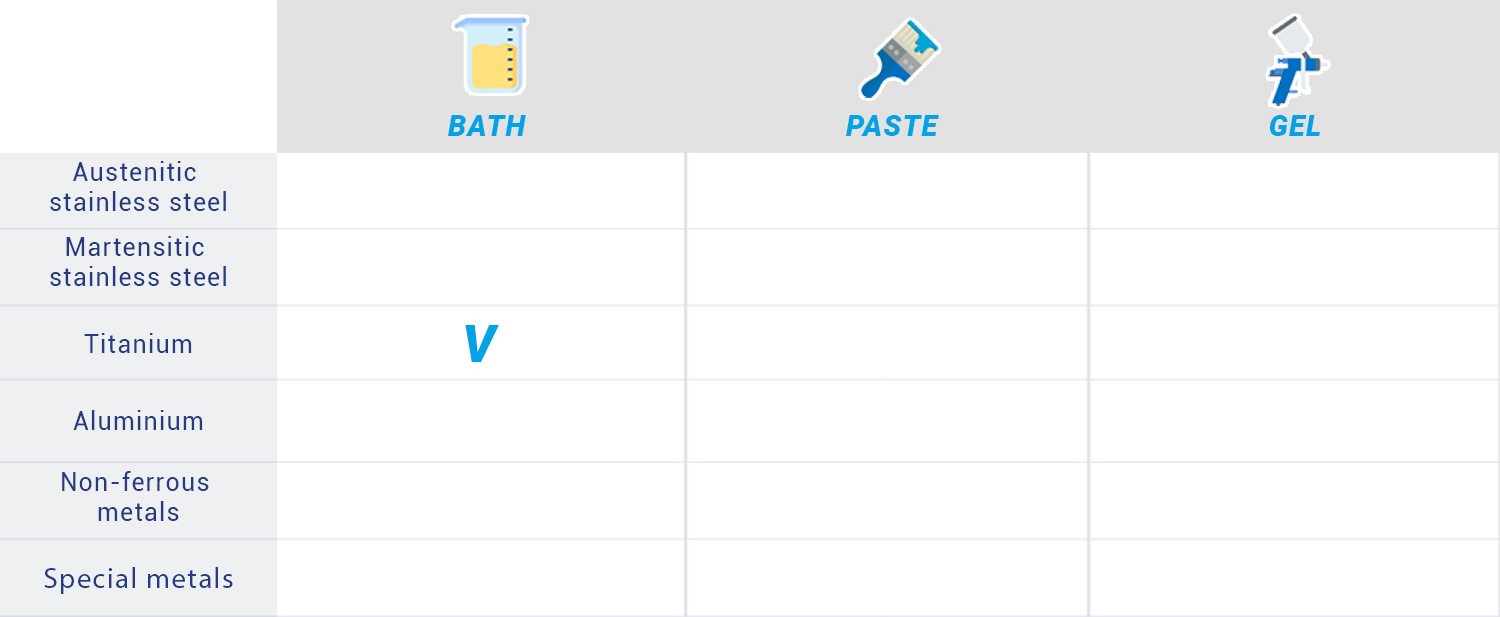

QUEL PRODUIT CHOISIR ?

CELA DÉPENDRA DE L’UTILISATION SOUHAITÉE

Le produit choisi dépendra du type de matériau traité (titane de type T40, T60 ou TA6V) et des exigences sur le produit à utiliser, mais également de la couleur souhaitée et du mode de fabrication de la pièce en titane. Notre produit Aupus ANOD TI vous permet, en outre, un traitement sans émission de vapeurs dangereuses. Afin de choisir le produit le plus adapté à votre utilisation, faîtes appel à notre équipe.

ANODISATION SUR LA FABRICATION ADDITIVE

L’électrolyte pour anodisation Aupus ANOD TI + est un produit spécialisé pour vos pièces issues de la fabrication additive. Avec ce produit vous allez notamment pouvoir obtenir une large gamme de couleur. Qui plus est, il peut être combiné avec le produit de décapage Aupus DEC TI+ pour une meilleure préparation de surface au préalable.

NOS FORMATS

Toutes nos références d’électrolytes à appliquer en immersion peuvent être commandées par bidon, par fût et par container. Aussi, pour connaître leur contenance exacte et recevoir un conseil sur la quantité qui convient le mieux à votre utilisation, n’hésitez pas à prendre rendez-vous avec notre équipe.