TOUTE NOTRE GAMME D’ÉLECTROLYTES DE POLISSAGE

“Shine bright like a diamond”

Appliqués en immersion, nos électrolytes de polissage apportent brillance, éclat et une meilleure résistance à la corrosion à vos pièces.

ÉLECTROLYTES DE POLISSAGE

NOTRE GAMME POUR L’ELECTROPOLISSAGE DES INOX

Découvrez toute notre gamme d’électrolytes de polissage pour aciers inoxydables et leurs différentes applications.

Aussi, n’hésitez pas à nous contacter pour trouver le produit qui correspondra le mieux à votre besoin.

>>Electrolyte de polissage Aupus 912 A

>>Electrolyte de polissage Aupus 912 AM

>>Electrolyte de polissage Aupus E 268 I

>>Electrolyte de polissage Aupus E 269 I

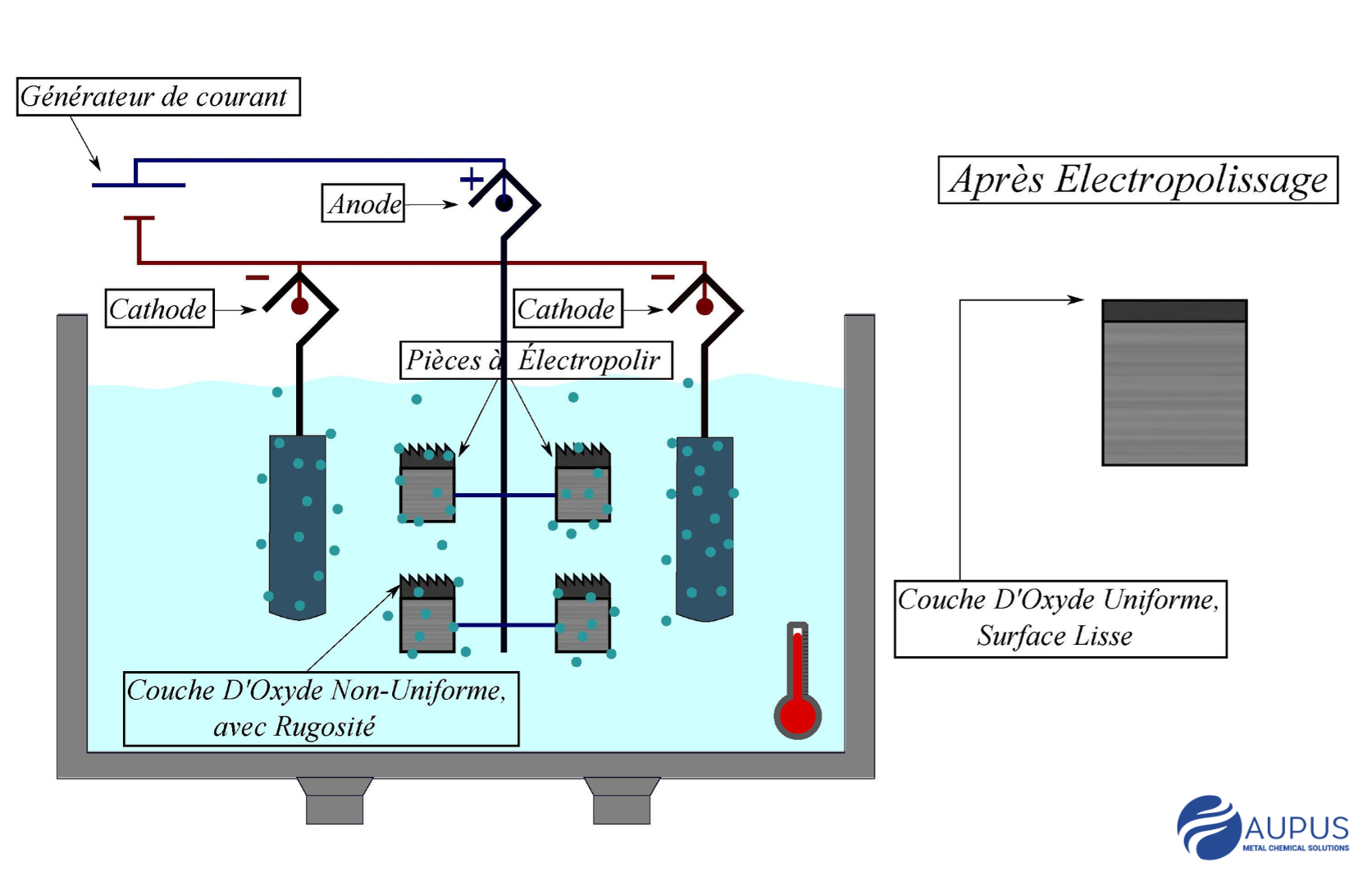

LE PROCÉDÉ DE POLISSAGE ÉLECTROLYTIQUE

Ce procédé électrochimique vient éliminer l’oxyde de fer présent en surface de vos aciers inoxydables afin de révéler l’oxyde de chrome, à l’origine de la résistance à la corrosion. De ce fait, l’objectif est multiple : niveler la surface de vos pièces et les rendre plus brillantes ainsi qu’optimiser la résistance à la corrosion. En outre, ce procédé permet aussi d’ébavurer une pièce usinée. Nos électrolytes de polissage peuvent être combinés à nos lignes de traitement.

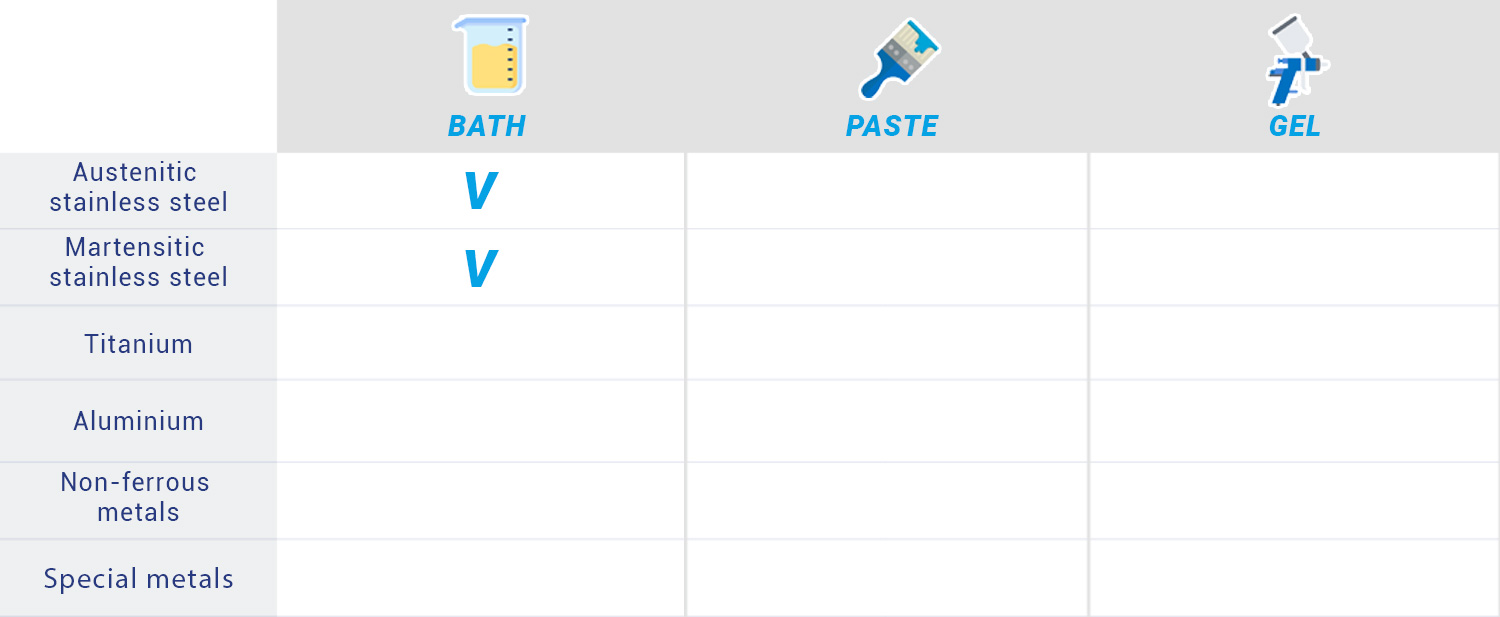

QUEL PRODUIT DE POLISSAGE ÉLECTROLYTIQUE CHOISIR ?

Le produit de polissage électrolytique choisi dépendra du type de matériau traité, les contraintes dimensionnelles et les exigences sur le produit à utiliser. L’ensemble de nos produits de polissage électrolytique pour aciers inoxydables sont d’ailleurs conformes à la norme ASTM B912. Afin de définir le produit le plus adapté à votre utilisation, notre équipe vous accompagne dans l’étude de votre besoin.

NOS FORMATS

Toutes nos références d’électrolytes de polissage à appliquer en immersion peuvent être commandées par bidon, par fût et par container. Pour connaître leur contenance exacte et recevoir un conseil sur la quantité qui convient le mieux à votre utilisation, n’hésitez pas à prendre rendez-vous avec notre équipe.